Engineering division

Arial Industries has built up over more than 15 years a recognized expertise in mechanical engineering, plant design, electrical and embedded systems.The main domains are described hereafter:

Mechanical engineering

Design

- Conceptual design

- CAD Design

- Drawing, functional dimensioning, tolerancing

- Design of metallic and composite primary structure

- Mechanical Systems Installation

- Aircraft interior design

- DMU Management

- Configuration management

- Jig&tools and tests benches design

Tools

- CATIA V5 & V6, CADDS 5, CATIA V4, VPM, PDM Link, ProEngineer, CREO, AUTOCAD, SOLIDWORKS, SOLIDEDGE, TREND, GILDA, 3DVIA

Calculation

- Global Modeling (GFEM)

- Detailed Modeling (DFEM)

- Linear, nonlinear, dynamic, static FEA/FEM analysis

- Fatigue and damage tolerance

- Justification, certification

- Concession

- Life Extension

- Calculation/Test correlation

- SRM calculation (Service Repair manual)

- Topology optimisation

- Impact and crash analysis, rapid dynamic

- Fluid mechanic and aerodynamic

- Structural calculation (ASME, CM66, EUROCODES, RCC-M/MR)

Tools

- Patran, Hypermesh, ANSYS Workbench, ANSA, Nastran, SAMCEF, SAFE, NASGRO, ANSYS, Abaqus, Optistruct, ISAMI, PSN, ASSYST, Stream, Comsol.

Plant design

- 3D Design (CATIA V5 Equipment and Systems, PDMS)

- Isometrics Drawings (ISOGEN)

- Civil engineering design and layout.

- Technical specifications for the Suppliers

- Supervision and monitoring

- Electrical diagram

- “ Cabling diagram” & “ One line diagram”

- PID & PFD network diagrams

- Mechanical, electrical and fluidics networks

Tools

- JAVA, C ++, C, ADA, Matlab / Simulink, C #, .NET, DOORS, SABER, VISAGE, ATOLE

Embedded system

System design

- Technical design documentation

- Configuration Management

- Multi-Standards management

System Support

- Design office development support

- Quality assurance

- Optimizations and corrections (MAP, FAL …)

- Production support

Validation & Verification

- Preparation of specific technical documents

- System behaviour evaluation after test bench (simulator or flight test)

- Design Review and Certification

Tools

- JAVA, C ++, C, ADA, Matlab / Simulink, C #, .NET, DOORS, SABER, VISAGE, ATOLE

Standards

- DO178, ED153, DO254, ABD100, ABD200, DO160, GRESS, ARINC, AFDX

Support and training center

ARIAL Industries is an officially approved and accredited training centre.

We offer software and technical trainings for companies, organizations and individuals with a “pôle emploi” agreement or within the framework of the Personnel Training Account.

We offer training courses on:

- Catia V5 (solid, surface, assembly, drawing)

- Autocad

- SEE XP

- SEE VISIO

- Technical drawing

- Static calculation

- Fatigue calculation

- Functional dimensioning and tolerance stackup analysis

- Geometric dimensioning and tolerancing (GD&T)

- Project follow-up

- Design of welded structures

Since 2009 ARIAL Industries has a dedicated team on ITER site performing the tests – the training and the certification of ITER staff and contractors. (CATIA V5 Mechanical – Equipment and System – ENOVIA V5)

Since 2016: ARIAL Industries provides the training on IGE+XAO SSD (See System Diagram) of F4E schematic activities in Barcelona and Cadarache premises.

![]()

Manufacturing division

Since its foundation in 2001, ARIAL Industries has developed a strong expertise in design and engineering in aeronautics, nuclear, space and transportation and has been working for several years on the implementation of a global design /manufacturing offer.

Our technical team is made up of a hundred technicians and engineers, complemented by strong partnerships with manufacturers (machining, boiler making, surface treatment, metrology, ect.)

We have an assembly hall within our Toulouse and Aix-en-Provence premises.

In addition, ARIAL Industries is involved in the development of a waste reprocessing and waste-to-energy conversion using the CARBOLYSE TM process (ELYSE Technology Company) ( http://www.elyse-technology.com/ )

The main domains are detailed below:

Production follow-up

- FAL AIRBUS Helicopters Follow-up since 2002

- Non-compliance management

- Bring into conformity the electrical devices

- Analyse the assembly line feedbacks

- LEAN and continuous improvement

- Management, follow up and scheduling

- Virtual plant and flow simulation with DELMIA

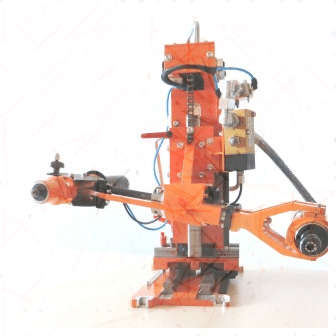

Turnkey tooling

- Assembly, drilling and machining tools

- Nuclear dismantling tools

- Gloveboxes

- Platforms and walkways

- Spreader and lifting tools

Tools

- Catia V5, Solidworks, Autocad, ANSYS Workbench …

Manufacturing

- Machining: turning, milling

- Welding: TIG, MIG-MAG, Arc

- Boilers: small and medium capacity

- Mechanical welding,

- Special purpose machine,

- Jig & Tools,

- Test benches,

- Mechanical assemblies

Domains

- Mechanics / Boiler making / Piping / Machining

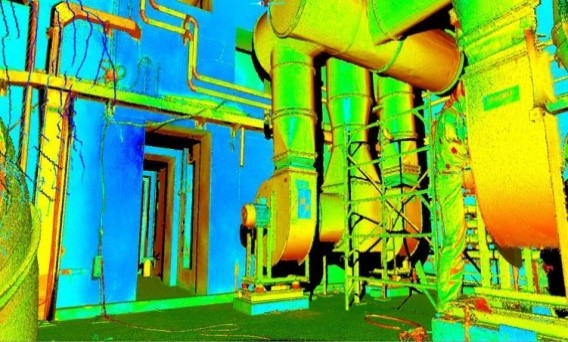

3D Metrology and Scan

- 3-Dimensional measurement using Laser Tracking of individual parts or assemblies

- 3D laser scan from a few millimetres to 300m

- Reverse-engineering

Tools

- API T3-40, Faro X330, VIALUX Z, METROLOG XG; Polywork, GEOMAGIC, FARO-SCENE

Maintenance

- Maintenance procedures, maintenance plan, maintenance operation methods

- Maintenance planning management

- Management and technical Supervision

Domains

- Mechanics / Boiler making / Piping / Hydraulics / Pneumatics / Regulation

Multi-technology Hybrid Manufacturing

Hybrid manufacturing is the association of additive manufacturing with other traditional processes such as machined parts, moulding and composite lay-up while optimizing parts design

- Additive Manufacturing (3D printing)

- Topology optimization

- Composite Lay-up on 3D printed core

Casting in 3D printed mould